What do we do? Whatever it takes.

Utilizing the latest technology and equipment, the Nix team always meets the challenge with a commitment to doing the job right the first time, every time. We specialize in solving complex underground problems with meticulous planning and precision execution.

New Construction Technology

Pilot Tube

Guided Bore

A hollow steel tube through which a theodolite (precise survey instrument) and a LED target are used to guide line (direction) and grade (slope) for a bore.

Steering Head

Guided Bore

Equipment pushed through the ground in front of a bore that utilizes ‘wings’ or ‘flaps’ to push against the surrounding soil to accurately ‘steer’ the pipeline into place .

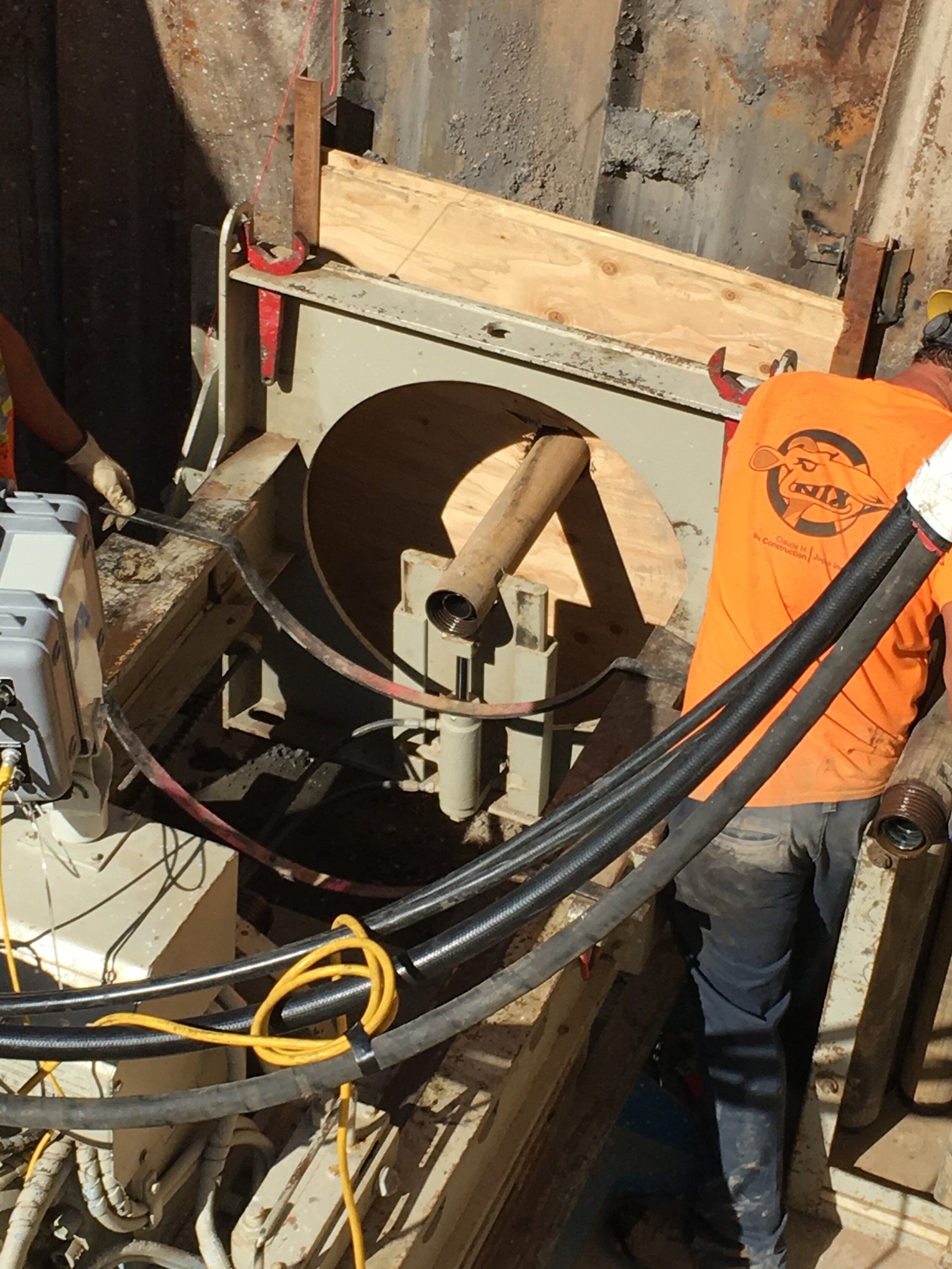

Pipe Jacking

Tunnel Bore

Hydraulic cylinders specially designed for jacking (pushing) pipes or steel casings through the ground behind the steerable tunnel boring machine (TBM). The TBM is manned by an operator who observes soil conditions and monitors line and grade to ensure a precise installation.

Pipe Jacking

Auger Bore

Also uses hydraulic cylinders to jack or push pipes or steel casings through the ground but it also uses augers to remove the soil from the pipeline. Auger boring can be coupled with pilot tubes or a steering end for installations that require precision.

(Guided or Unguided)

Pipe Ramming

Steel casing is driven or ‘hammered’ through the ground using an pneumatic piston. Pipe ramming can also be guided for a more accurate installation by using pilot tubes and a reaming head in advance of the steel pipe or casing.

Hand Tunneling

Sometimes using a machine is not an option and you have to do things the old fashioned way. This calls for dedicated, strong, and industrious employees who aren't afraid of getting dirty and sweating.

Pilot Tube

Micro-Tunneling

The original use of the pilot tubes, this method first pushes the tubes through the ground to create a ‘pilot’ path for the pipeline to follow. Then the machine, equipped with hydraulic jacks, pushes the new pipeline along the pilot path and simultaneously removes the soil from the interior of the pipeline. The machine is also used to install the pilot tubes used for guiding auger bores and pipe rams.

Rehabilitation

Services

Pipe Bursting

A bursting head moves inside of the old pipe, while simultaneously pulling a new pipeline. The head breaks apart the old pipe, sending the remnants into the surrounding soil.

Grouting

Annular Grouting:

Using cementitious grout to fill the space or void between an existing pipe and a new pipe that has been ‘slipped’ into the old one.

Contact Grouting:

Using cementitious grout to fill the void between a new pipe that has been tunneled and the undisturbed ground surrounding that pipe.

Pipe Abandonment:

Grout can be used to completely fill old pipelines where removing them is not practical or recommended to avoid problems on the ground surface should the old pipeline completely deteriorate. I.e. sink holes.

Slip Lining

Pushing a new, slightly smaller, usually smoother, pipe inside an existing and often deteriorated pipeline to extend the life of the utility. Grouting is often used between the old and new to improve the structural integrity of the rehabilitated pipeline.